Complete Automated Plating on Plastics Line-Item#346

Complete Automated Plating on Plastics Line-Item#346

Description

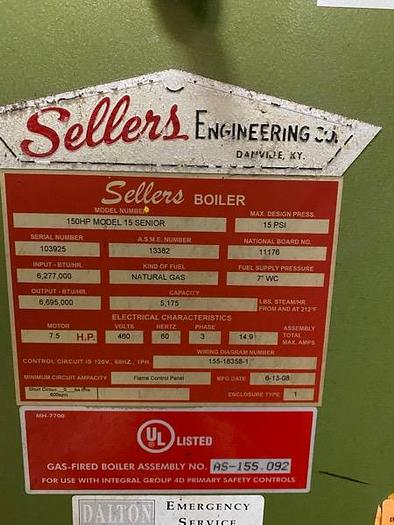

Complete Automated Plating on Plastics line USA built in 2008 7 laser positioned center lift hoists, each with 3,000 pound capacity Line was processing 13 loads per hour 47 tanks 132” long x 66” deep x various DOT widths ranging from 24” to 168”. Tanks vary in construction and include titanium lined SS, 1” thick polypro, stainless steel and lined carbon steel Control panel with Mitsubishi motor controllers and Allen-Bradley PLC-5. Complete two lane steel superstructure approximately 165’ x 44’ with support 10 feet on centers 88 steel carts to move flight bars to the line. No flight bars available. Rectifiers (many recently rebuilt) include: 1 unit Darrah 10V 12,000A, air cooled 7 units Darrah 12V 4000A, air cooled 8 units Darrah 12V 3000A, air cooled (1) Slimline 6500 GPH disc filter Tanks are as follows: ∗ Titanium lined SS tanks: 1 @ 36” DOT x 66” deep x 132’’ 2 @ 48” x 66” deep x 132” ∗ 1” thick poly-pro tanks: 14 @ 24” x 66” x 132” 3 @ 78” x 66” x 132” 5 @ 168” x 66” x 132” ∗ Stainless steel tanks: 2 @ 36” x ^^” x 132” 2 @ 48” x 66” x 132” 1 @ 28” x 66” x 132” ∗ Lined steel tanks: 3 @ 2 station counter-flow 36” x 66” x 132” 9 @ 24” x 66” x 132” 2 @ 30” x 66” x 132” 3 @ 36” x 66” x 132” ∗ Holding tanks: 2 units 1” polypro construction 48” DOT x 96” deep x 96”long Large quantity of titanium anode baskets designed for this machine: 104 units 2.5” x 6” x 36” tall, various perf & mesh, Square profile hooks 352 units 2.5” x 6” x 52” tall, various perf & mesh, Square profile hooks Assorted portable chillers available: 1 unit Rite Temp 20 ton capacity, 45F output 2 units Rite Temp 10 ton capacity, 45F output 1 unit Rite Temp 5 ton capacity, 45F output (2) exhaust scrubbers @ 40,000 cfm with blow down tanks and pumps (1) complete, flow through conventional destruct waste treatment system 75 GPM with chrome destruct, control panel, and filter press: 5650 gal never used fiberglass EQ tank 5650 gal vertical stage 1 treatment tank 2 units 3000 gal vertical treatment tanks 80 GPM inclined plate clarifier Sand filter and final filter/discharge monitoring stages 2 units 100 gal reagent day tanks with dosing pumps & probes PacPress filter press, 800mmx800mm filter plates (30 plates) with automatic closure and plate shifter, 10 cu.ft. capacity (1) Sellers Engineering boiler , 75 HP 6,700,000 BTU provided 4 hour heat up time for the line

Specifications

| Condition | Used |

| Stock Number | 346 |

| ∗ all process tanks have coils installed | titanium, stainless steel, or Teflon |