Automatic Hard Chrome Rack Line-Item#362

Automatic Hard Chrome Rack Line-Item#362

Description

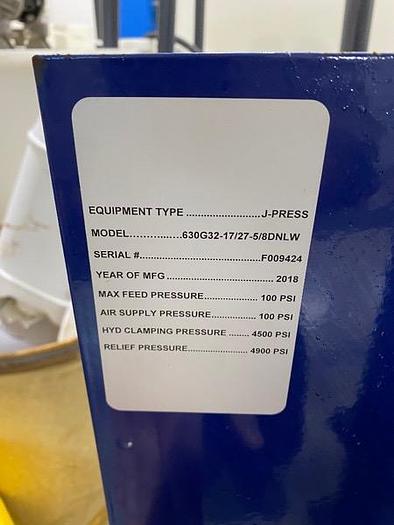

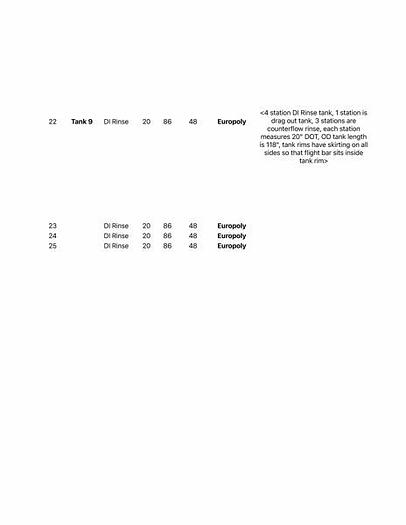

THIS SYSTEM CAN BE PURCHASED AS A WHOLE OR PIECEMEAL Built in 2018 by NPC and run for approximately 1 year before pandemic related issues forced ceasing operation. Line was built to hard chrome plate steel pipe for automotive suspension assemblies. 25 stations on the line comprised of 9 tanks (7 europoly tanks and 2 PVC tanks), a 2 station stainless steel dryer with automatic covers and a unique rotating load/unload station. Nominal tank inside dimensions are 23” DOT x 86” CDOT x 48” deep. 8 hard chrome plating stations, each with its own plate and frame cooling system and 12V 8400A air cooled, switchmode rectifier. Electro-clean station is equipped with a 12v 4200A air cooled, switchmode rectifier. Line includes an automatic saddle washdown and automatic saddle cooling system – all tanks have tank rim skirting facilitating use of the saddle washdown system; flight bars sit inside tank rim skirting. Flight bars with spring loaded pipe fixtures measure 111” long x 8” wide x 45” top to bottom. Flight bars are constructed of a combination of stainless steel, titanium and titanium clad copper while fixturing is a combination of titanium and plstisol coated copper. 4 railrider type hoists, laser positioned, gear driven traverse, 1500 pound capacity webbing lift; hoists have remote control pendants as well as on-board controls for manual operation if necessary. 3 hoists have automatic drip trays while the 4 th hoist, servicing the dryer and load/unload positions does not. Flight bars carry dual sided racks, plating tanks are set up with anodes on flight bars for ease of service; there are 3 anode runs per each plating station (2 on outsides of rack, 1 on center between racks). Machine has complete enclosure built of epoxy coated steel, polycarbonate and aluminum. Operator access is provided by way of bi-fold access doors at each station; doors are equipped with proximity switches to prevent operation with doors open. Machine enclosure measures 15’8” tall and 13’9” wide without operator catwalk (32” wide fiberglass operator catwalk on either side of machine), line is approximately 73’4” long including load/unload stations but not including support equipment area. Line support equipment includes: RO system – 2 train system; 2 high pressure pumps, 9 membranes, 40GPM each train (80GPM total) with water softening, ion exchange, and product water storage tank. Italian built Veolia Evaled chrome evaporator and recovery system model E 6000V3 KT4, with PLC controls, cone bottom evaporator tank, tube and shell condensers, all stainless steel, food grade system. Chrome cycling and dosing tank for automatic control and additions of chrome solution recovered via evaporator system. Alkaline exhaust scrubber and blower, 7650 m3/hr. Chrome exhaust scrubber and blower, 19,517 m3/hr with BLC Industries HEPA filter in exhaust stack. York Chiller, model YLAA0100SE46, air cooled 110 ton chiller, R410A refrigerant. Chrome electrowinning recovery tank with titanium anodes, PVC tank, 12V 1500A air cooled switchmode rectifier, tank level control and pumping system. 1 europoly chrome waste collection and pumping tank. 2 europoly rinse waste collection and pumping tanks. 4 europoly tank maintenance/dump collection tanks. 6 flight bar rolling carts.

Specifications

| Condition | Used |

| Stock Number | 362 |